Designed for auto handling operations

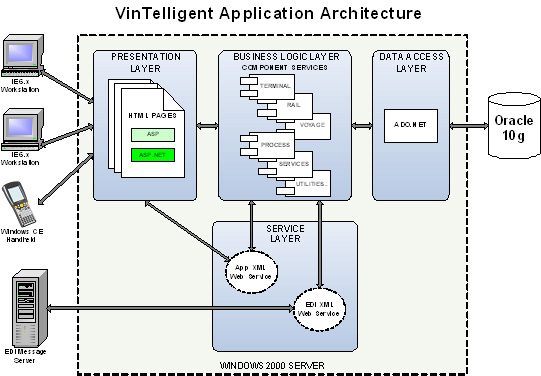

Web-based system; allows access anywhere and at anytime.

Real-time data input improves productivity and management effectiveness

Multi-terminal access provides complete and timely information across the company

Automated data collection (Handhelds and Fixed Scanners) increases accuracy and productivity

EDI module provides seamless integration with all trading partners

User friendly interfaces that are easy to learn

Terminal is the base module that supports essential terminal operation. The Rail and Vessel modules use Terminal Gate functions in their process flows. Terminal includes the Yard Planning feature as well as other additional feature listed below. Many Terminal features are available on handheld devices, as well as on the desktop, to enhance productivity.

Gate

Receive Assigns bay location using parking algorithm. Sets units to in-inventory status and sends arrival message to trading partners.

Truck Load List Facilitates creation of truck loads. Haulaway carriers may create truck loads in VinTelligent via EDI messages.

Dispatch Removes units from inventory and sends shipped message to trading partners. Units may be dispatched singly or by Truck Load List.

Inventory Management

Inspection Records results of inspections. Tracks inspections by type, such as “Receipt Inspection”.

Holds and Releases Records user-defined hold codes and subsequent releases. Supports multiple concurrent holds. Sends hold and release messages to trading partners and accepts holds and releases from trading partners via EDI.

Physical Inventory Supports physical inventory and reconciliation for all or part of the yard. Self-reconciles as events are recorded.

Rebay Assigns bay locations using the parking algorithm for yard moves. Sends yard move message to trading partners.

ASN Management

Routing and handling are directed by Advance Shipping Instructions (ASNs) typically received via EDI. VinTelligent also supports manual update of shipping instructions, either by individual ASN or in groups, and ASN reporting.

Yard Planning

Yard Planning is a powerful tool that is used to assign the best open yard space to a unit. The parking algorithm is based on flexible user-defined rules and supports assignment of units to single vehicle bays, multiple vehicle bays and load lanes. It enforces all restrictions set for the actual yard location such as the maximum number of vehicles in a bay and the bay status (active / inactive).

General

Events and Statuses Enforces business rules regarding status changes. All events and status changes are recorded and may be viewed on the activity log.

Reports ASN, inventory, activities, status, inspection, yard capacity and other reports are provided.

Dashboard - The dashboard provides a one-page management snapshot of ongoing terminal activity.

VinInsight - VinInsight is the tool that allow operators to give their customers direct access to reports on their own data.

Security - Role-base security configures user access as appropriate for each job function.

Archive - Maintains high performance of active operations by archiving completed transactions at user-defined intervals. Data is viewable on archive reports

Message Center - Message Center is the control center for the monitoring and managing EDI messages.

The VinTelligent Rail Module, in conjunction with the Terminal module, provides comprehensive support for rail ramp operations. Yard Planning enables definition of parking logic to meet specific needs such baying by dealer area to facilitate truck loading or in load lanes to speed up railcar loading. Many rail features are available on handheld devices, as well as on the desktop, and may be used on the yard and at the track. Fixed scanners may be used to optimize receipt of vehicles through the plant gate.

Railcar Management

Spotting Records railcar track location and condition (empty, loaded, bad order).

Ready To Pull Sends a message to the railroad that the cars are ready to pull.

Releasing Removes railcar from the track and sends shipped messages for units loaded in railcars.

Track Sheet Displays current status of all railcars at ramp.

Inbound Flow

Bay Assignment Automated bay assignment speeds unloading of railcars by pre-assigning bays and generating bar-coded bay tickets.

Grounding Sets units to in-inventory status and sends arrival messages to trading partners.

Reconciliation Report identifies discrepancies between the units planned for grounding and those actually grounded.

Truck Load List Facilitates creation of truck loads. Haulaway carriers may create truck loads in VinTelligent via EDI messages. (Terminal Module)

Gate Dispatch Removes units from inventory and sends shipped message to trading partners. Units may be dispatched singly or by Truck Load List. (Terminal Module)

Outbound Flow

Gate Receive Assigns bay location using parking algorithm. Sets received units to-in inventory status and sends arrival message to trading partners. (Terminal Module)

Load Planning Plans railcar loads. Sets up railcar strings for automated loading.

Rail Loading Automated loading scans units as they are driven up the buck ramp and automatically records railcar, deck and position for each unit. Manual loading allows user to specify railcar, deck and position. Both options send loaded status messages to trading partners

Reconciliation Report identifies discrepancies between the load plan and the actual load.

General

Events & Statuses Enforces business rules regarding status changes. All events and status changes are recorded and may be viewed on the activity log.

Reports Specific reports provide details on railcar activities and statuses. Rail Load Planning Reports provide basis for railcar allocation by destination

The VinTelligent Vessel Module, in conjunction with the Terminal module, provides comprehensive support for marine terminal operations including handling of vehicles and unitized cargo, such as pallets and bundles. Yard Planning, enables definition of parking logic to meet specific needs such baying by discharge port to speed up vessel loading. Many vessel features are available on handheld devices, as well as on the desktop, and may be used on the yard and at the dock. Fixed scanners may be used to optimize receipt of vehicles through a plant gate.

Voyage Management

Vessel Definition Defines vessels that call at your port, including deck/bay, hatch/hold and section.

Voyage Route Sets up voyage routes. Records actual arrival and departure date/times.

Import Flow

Discharge Planning Speeds unloading of vessels by pre-assigning parking spaces and generating bar-coded parking tickets.

Discharge Sets units to in-inventory status and sends arrival message to trading partners.

Reconciliation Report identifies discrepancies between the discharge plan and the actual discharge.

Truck Load List Facilitates creation of truck loads. Haulaway carriers may create truck loads in VinTelligent via EDI messages. (Terminal Module)

Gate Dispatch Removes units from inventory and sends shipped message to trading partners. Units may be dispatched singly or by Truck Load List. (Terminal Module)

Export Flow

Gate Receive Automatically assigns parking spaces using rules defined in Yard Planning. Sets received units to in-inventory status and sends arrival messages to trading partners. (Terminal Module)

Load Planning Updates status of units to planned for loading and records planned load vessel location (deck/hatch/section). Load Planning Reports assist in vessel load planning.

Vessel Loading Scans units as they are driven up the ramp and records loaded status and vessel location. Sends loaded status messages to trading partners.

Reconciliation Report identifies discrepancies between the load plan and the actual load.

The Process module supports post-production processing -- modifications, repairs and periodic maintenance for vehicles, as well as defining jobs such as crating or bundling for non-vehicle cargo. The basis of the Process module is the Job. All details of jobs may be defined, including tasks, parts and pricing. Job type dictates work flow requirements for the job. Jobs may be assigned via EDI, manually or automatically. Move jobs utilize the Yard Planning feature to determine the next parking space. Many Process features are available on handheld devices, as well as on the desktop, and may be used on the yard and in processing areas.

Job Setup

Job Definition Defines jobs and set all parameters for managing job.

Part Setup Defines parts and kits.

Task Setup Defines job tasks. Tasks may be copied from job to job.

Bill To Party Assigns Bill To Parties to jobs.

Kit of Services Defines a “kit” of jobs that may be automatically assigned.

Job Assignment

Mass Assign Assigns jobs to a group of vehicles or cargo, as for a manufacturers’ campaign.

VIN Assign Assigns one or more jobs to a specific vehicle or cargo.

Job Management

Plan Jobs Plans repair and modification jobs and creates work orders.

Track Jobs Updates and completes repair and modification work orders as well as field jobs and PDI.

Track PDI Special user interface optimizes completion of PDI checklists.

Move Jobs

Plan Moves Plans movement of units from one processing area to another or assigns a pre-defined move sequence.

Driver Next Move Using the moves set up by Plan moves, this handheld function automatically assigns the driver a vehicle to move and its next yard location. After the move, the driver records move completion.

Track Moves Updates and completes move jobs.

Move Sequences Defines move sequences.

General

Events & Statuses Enforces business rules regarding job status changes. All events and status changes are recorded and may be viewed on the activity log.

Reports Specific reports provide details on job and work order statuses and activities.